Automatic Continuous Tunnel Washer

Product Details

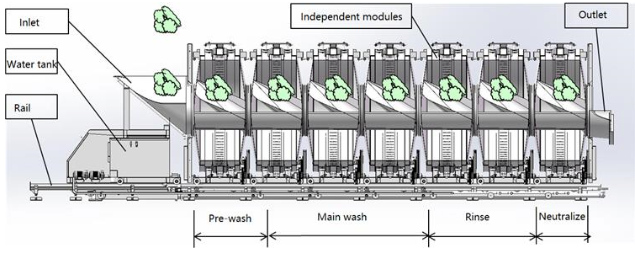

Flexible modules, variable frequency drive motor control (7-15rpm) for each module according to the linen type and dirty degree so different washing mechanical force to flexibly meet different linen continuous washing requirement and fast delivery.

All double drum design, both 270°and 360°drum rotation for optional use to ensure optimum mechanical action for different kind of linens.

2 meter diameter drum, 40.2:1 loading ratio, up to 0.3G of strong washing mechanical force and erosion force to achieve stronger cleaning ability, easy to deal with all kinds of linen, greatly shorten washing time, reduce consumption of water, steam, chemical (Note:compared to other tunnel washer, water saved by 30%, steam by 20%, chemical by 20%).

Each module is individually programmable and have inlets for water, chemical, drainage, temperature probes and more, washing process separation surface can be adjusted or increased or decreased.

Pre-wash module equipped with high-pressure pump for recycle scouring and washing to improve the prewash treatment effect.

The tunnel may be opened to provide the access between any two modules in less then 10 minutes, thus the operator is then free to carry out routine maintenance or remove an obstruction in complete safety.

Addition of modules to enlarge the production of the tunnel may be carried out in two days.

Construction is entirely in grade AISI 304 stainless steel (other grades optional).

Independent modular design with open type panel convenient for repair and seervice, and easy to add module for future increasing capacity demand.

Self-developed automatic control system based on WIN7 with a strong human-computer interaction programming, data monitoring and statistics, remote monitoring, diagnosis and service.

Drawing

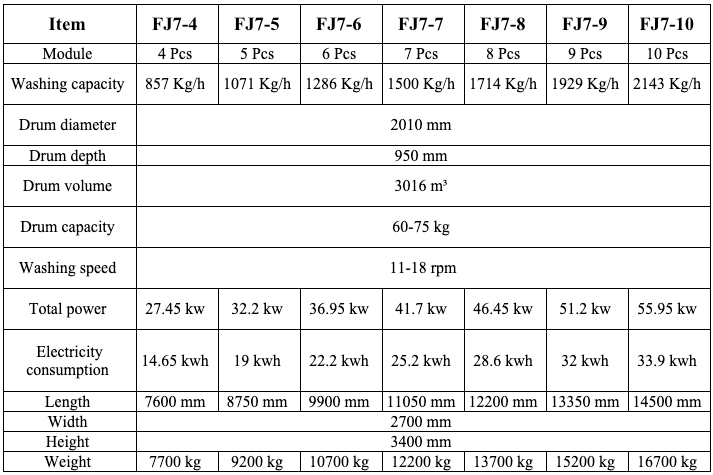

Parameters